Grain augers and grain conveyors are both designed to serve the same general purpose – moving grains, legumes, rice, nuts or dry bulk commodities

So while they are both capable of handling conventional types of crops (e.g. wheat, barley, sorghum), there are some crops which are better suited to a conveyor compared to an auger.

One such type of crop is the humble chickpea.

In this blog post, the experts at Westfield take a look at why a conveyor is the ideal choice for handling chickpeas compared to an auger.

Grain conveyors, also referred to as grain belts or tubeveyors, are widely known to be the gentlest means of handling high value crops. By design, a grain conveyor minimises impact damage to grain during high capacity handling whilst maintaining the value of delicate commodities such as chickpeas.

Chickpeas, being a dicotyledon, have two seed halves and are more prone to damage during handling. They can also be quite tough and abrasive by nature and will therefore shorten the life of a grain auger quite dramatically.

A conveyor carries grain on the belt in contrast to an auger which physically pushes grain through the auger tube via the spiral flighting. This means that with an auger, there is a risk of mechanical damage being caused to the grain such as chipping to the seed coating or cracked and broken kernels.

A well-made conveyor should be as smooth internally as possible in order to reduce belt friction, lower power requirements and reduce grain damage. This can be achieved by using tubing that has one seam along the top of the tube, rather than a spiral welded tube.

The seed coats of grain legumes, particularly chickpeas, are vulnerable to weathering once the seed has reached physiological maturity. Hence rain falling on a mature crop can lead to a high amount of splitting if the crop is moved with a grain auger when harvesting recommences.

Lastly, while the capital outlay for a conveyor is higher than an auger, there is definite value in the additional outlay when growing and handling chickpeas. Gentle handling with a belt conveyor means less seed coat damage, less splitting, less admixture and generally higher value grain.

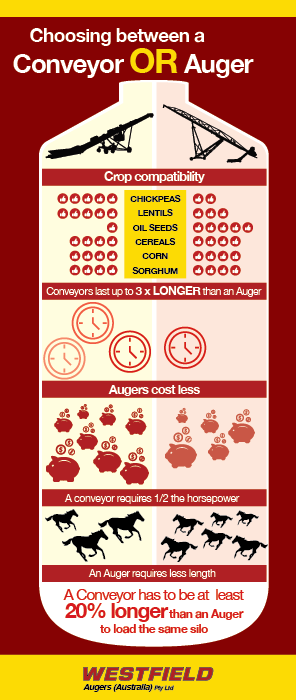

The following is a handy graphic which can be further used to weigh up the pros and cons of using an auger compared to a conveyor for different types of grains.

Looking for further advice on using conveyors for handling chickpeas? Talk to Westfield.

Our expert team all come from farming backgrounds, so we have a real understanding of the importance of choosing the right grain handling equipment to meet your needs.

While gentle on grain, our grain conveyors are built tough and engineered from the ground up for a long service life. Each grain belt is designed to handle a broad range of grain quality and moisture content to ensure your grain flows smoothly.

We have also designed the belt return to be carried on special belt support rollers which reduces friction on the return side to the absolute minimum. This leads to a longer belt life, minimal stretching and less need for adjustments. The longer the conveyor, the more important this becomes.

To find out more, simply click here to get in touch with us today.